For those who work in heavy dust environments for extended periods, a mask has evolved beyond being a mere protective gear; it has become the "first line of defense" safeguarding respiratory health. Many novices often fall into the misconception that "just any mask will do," unaware that ordinary masks are virtually useless in the face of heavy dust. Today, let's clarify for beginners how to precisely select a dust mask suitable for heavy dust environments.

First, we must clarify the core premise: in a heavy dust environment, ordinary masks are completely inadequate, and the most basic choice is a half-face mask. When selecting the material for the mask, there is a clear priority - to choose food-grade liquid silicone material first. This material has outstanding advantages, with a soft texture that is skin-friendly, better fitting the facial contours, reducing the possibility of dust infiltrating through gaps, and causing no strong discomfort even when worn for a long time. It is particularly important to avoid rubber-material masks, which not only lack softness and fit poorly, but also easily cause skin allergies, bringing additional troubles to long-term work.

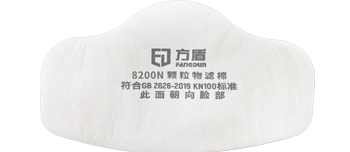

Choosing the right face mask is crucial, and the selection of filter cotton is even more pivotal, as it directly determines the effectiveness of protection. Here's a core advice for beginners to avoid pitfalls: directly opt for KN100 or KP100 grade filter cotton, and refrain from choosing the KN90 or KN95 series for convenience or cost savings. In heavy dust environments, the filtration efficiency of 90 and 95 series filter cotton falls far short of the demand, unable to effectively prevent fine dust from entering the respiratory tract. Prolonged use can still pose a threat to health.

Some novices may be confused about how to distinguish and choose between KN100 and KP100. Actually, the core criterion is the type of dust in the environment: if the dust in the working environment is oily particulate matter, such as automobile exhaust, cooking fumes, oily dust generated by mechanical processing, etc., then choose KP100 grade filter cotton; if it is dry non-oily particulate matter, such as cement dust, stone powder generated by stone grinding, wood chips from wood processing, etc., then prefer KN100 grade filter cotton.

In addition, there are two special situations that require attention: If the work environment is accompanied by odors in addition to dust, such as the smoke and odor produced by electric welding, or the irritating smell of chemical dust, it is recommended to choose filter cotton with an activated carbon layer. The activated carbon layer can effectively adsorb odors, enhancing the wearing comfort and the comprehensiveness of protection. If the dust concentration is extremely high and contains toxic gases, filter cotton alone cannot meet the protection needs. At this time, it is recommended to add a gas filter box to the half-face mask to achieve dual protection against dust and toxic gases, ensuring more comprehensive and reassuring protection.

To summarize, novices selecting dust masks in heavy dust environments should remember the core logic of "first choosing the right mask material, then accurately matching the filter cotton level". Based on the actual situation such as dust type, whether there is odor or toxic gas, etc., they can avoid most misunderstandings and choose a dust mask that truly suits them and can effectively protect their health. After all, in harsh working environments, choosing the right protective equipment is responsible for one's own health.

English

English