In work environments that are humid or have a risk of water splashes, special attention should be paid to the selection of dust masks. The electrostatic filter cotton is the core component of a dust mask. However, once it gets wet, not only will its core particle protection efficiency drop significantly, but the breathing resistance will also increase noticeably, ultimately leading to a significant reduction in the overall protective effect.

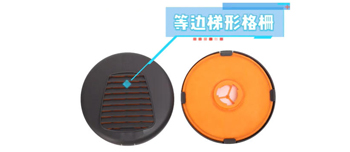

For work scenarios involving minor water splashes such as spraying and detection, it is recommended to use the Fj16 waterproof cover. This waterproof cover features an equilateral trapezoidal grille design, which guides water flow quickly and smoothly, effectively preventing splashes from contaminating and wetting the internal filter cotton, ensuring stable protective effects.

For work scenarios involving high water splash, such as anchor rod installation, tunneling, and shotcreting, we recommend using the FJ18 waterproof cover. It boasts triple protection against backflow, splash, and infiltration. Even in the face of heavy water flow, it can firmly secure the internal filter cotton, ensuring that the mask remains in optimal protective condition at all times.

In addition to the dedicated waterproof cover, we also provide the 6101P dust filter box with inherent waterproof properties. It adopts a fully enclosed outer box design, which can effectively isolate liquid splashes during operation. Even in scenarios such as rain or disinfection, there is no need to remove it, continuously ensuring protective effects.

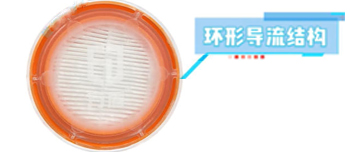

The 6102P dust filter box adopts an annular airflow guiding structure design, offering superior waterproof performance. Even if it comes into contact with water vapor or is splashed with water, it can stably maintain its core filtration efficiency. Additionally, the dust filter box is equipped with a visual window, allowing customers to intuitively check the usage status of the internal filter cotton without disassembly. This not only avoids waste or damage caused by repeated use of the filter cotton, but also prevents protection failure issues caused by filter cotton blockage.

English

English