During the processing of stone materials, processes such as cutting, grinding, and polishing generate a large amount of mineral dust. The crystalline silicon component contained in this dust is an "invisible killer" that poses a threat to the health of those engaged in the industry. The sensation of countless tiny dust particles squeezing into the nasal cavity is dry and rough, akin to fine sandpaper rubbing against the mucous membrane. The air is turbid and grayish-white, and amidst the roar of machine tools, dust can be seen tumbling and settling in the light beams, only to be lifted up again by the next round of cutting. Wearing a qualified dust mask in accordance with regulations is a key measure to block dust invasion and ensure respiratory safety.

Proper selection, wearing, and management of masks are not only responsible for the health of workers but also a basic requirement for safe production in enterprises.Ordinary masks can't block anything. After a day, the inside of the mask will be covered with a layer of obvious grayish-black dust, and the sides of the nose will also be black. The phlegm coughed out has a sandy texture. The dust in the stone factory is mainly non-oily particulate matter. The selection of masks should strictly follow relevant national standards and be scientifically chosen based on the dust concentration of the work scene.

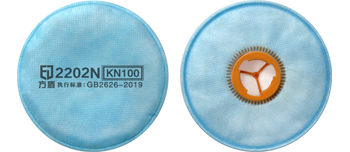

Based on the filtration level, KN100 masks have a filtration efficiency of not less than 99.97%, effectively blocking fine dust particles above 0.075 microns. They are the preferred choice for high-concentration dust operations such as cutting and grinding. KN95 masks have a filtration efficiency of ≥95%, suitable for auxiliary positions with lower dust concentrations such as factory inspections and material handling. KN90 masks have a filtration efficiency of only 90%, and can only be used as temporary protection for short-term low-risk operations. They are not recommended for long-term use in core processing procedures.

Masks need to be replaced promptly. Under normal circumstances, the use time of KN100 grade filter cotton should not exceed 8 hours. If there is dirt, damage, or a noticeable increase in respiratory resistance when wearing, the mask should be replaced immediately. Enterprises need to set up dedicated mask replacement points at workplaces to facilitate timely replacement for employees, and establish a record of protective equipment distribution to ensure that everyone can obtain qualified protective gear.

For reusable face masks, regular maintenance and replacement of expired filter cotton are required as per instructions, ensuring the mask remains clean and intact. Disposable masks should be discarded immediately upon any component failure and must not be reused after cleaning. Additionally, workers should avoid growing long beards or having foreign objects on their faces while wearing masks, as this may affect the fit between the mask and the face, thereby reducing the protective effect.

English

English